Table of Contents

The Need for Accuracy in Warehouse Management

From inventory management to order fulfillment, every aspect of warehouse operations relies on accurate data. A recent article on Supply Chain 24/7 outlines the need for accuracy in warehouse operations. It showcased that 15.1% responded to accuracy on a list of 10 different areas of improvement in warehouse operations.

Why do we need accuracy in a warehouse?

Inaccurate inventory data can cause stockouts and overstocking, resulting in revenue losses of up to 22%. For businesses striving to minimize errors and optimize processes, accuracy is key to operational efficiency and cost-effectiveness.

Accurate inventory data ensures that products are always available when needed, minimizing the risk of stockouts and optimizing costs by reducing excess inventory. This enables warehouse managers to efficiently plan and execute tasks, minimizing idle time and maximizing productivity.

Ultimately, warehouse accuracy directly impacts customer satisfaction. When orders are processed accurately and efficiently, customers receive their products on time and in good condition, leading to positive experiences and fostering repeat business.

How to Gain Accuracy in Warehouse Management?

Manual parcel measurements are prone to errors and inconsistencies eventually leading to the misplacement of items, incorrect inventory records, and ultimately, customer dissatisfaction.

Automating the parcel measurement process and providing accurate dimensional data addresses the accuracy needs in warehouse operations. Investing in automated data capture devices is one of the major efforts for warehouses looking to modernize and optimize their processes.

vMeasure parcel dimensioner signals a compelling role in building accurate SKU master data with its cutting-edge dimensioning solution for accuracy and efficiency.

vMeasure Parcel Ultima not only enhances accuracy but also provides mechanisms to efficiently utilize the data for inventory management. It also includes image and video capture capabilities to address claims and disputes effectively.

On the other hand, Deposco offers Bright Warehouse, a competent WMS (Warehouse Management System) solution providing enterprise-grade benefits like company-wide visibility and real-time data generation. It enables fast and accurate order processing, seamless scaling, and strategic order fulfillment strategies for businesses of all sizes.

Imagine having a parcel dimensioner seamlessly integrated with your WMS, making inventory management and order fulfillment a breeze while keeping costs down.

The need for accuracy is fulfilled by vMeasure Parcel Ultima and Deposco Integration.

What Will You Benefit from Deposco and vMeasure Integration?

The importance of modernization in warehouses enhances efficiency and competitiveness. The insights derived from the case study conducted by ZEBRA report that 77% of the people surveyed in the study believe that using technology to enhance the capabilities of workers is the most effective approach to implementing automation in warehouses.

Deposco and vMeasure Parcel Ultima integration brings significant benefits to warehouse operations.

#1 Build SKU Master Data

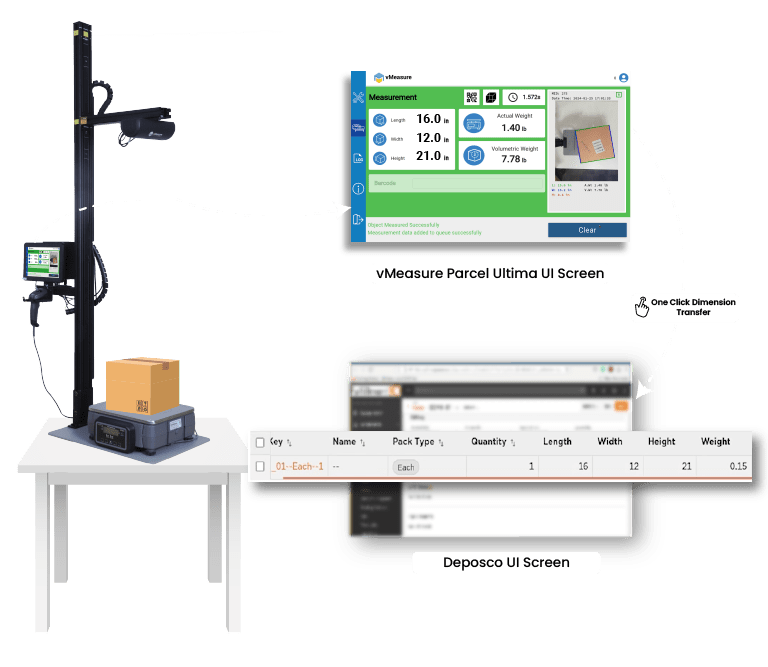

The accurate parcel dimensional data captured by vMeasure Parcel Ultima is automatically transferred to Deposco WMS (Warehouse Management System) with just one click, ensuring precise SKU master data. This lays a solid foundation for inventory management, order fulfillment, and other downstream activities.

#2 Accuracy and Reliability

This integration automatically transfers accurate parcel dimensions to Deposco’s WMS. This automatic transfer eliminates human errors from manual data entry and enhances the data integrity for a smooth warehouse operation.

#3 Simplified Integration in Just Few Clicks

With no-code API integration between Deposco and vMeasure Parcel Ultima, simple as it only requires a few clicks. This reduces the dependencies on IT resources for complex integration tasks, ensuring faster deployment.

#4 Improved Decision Making

Each warehouse varies in how it handles goods flow and logistics. Accurate parcel dimensions aid in decision-making for warehouse processes such as goods placement, picking, packing, distribution, and handling returns. This helps your managers to make quick, informed decisions for better resource allocation.

How Simple Is It to Integrate Deposco and vMeasure?

Now that you know the power of accuracy and automation. Let’s see how simple it is to integrate a parcel dimensioner with a Warehouse Management System (WMS).

Step 1:

Open the Deposco’s WMS, Bright Warehouse in your web browser

Step 2:

Connect Bright Warehouse and vMeasure Parcel Ultima via prebuilt API

Step 3:

Place the parcel on vMeasure Parcel Ultima and scan the barcode to trigger measurements

Step 4:

vMeasure Parcel Ultima captures the accurate parcel dimensions and automatically transfers the captured dimensions into Deposco’s WMS for further warehouse processing.

Integrating Deposco and vMeasure presents a powerful solution for elevating warehouse operations and addressing the critical need for accuracy. From the challenges of manual parcel measurements to the benefits of automation, we’ve explored how this integration streamlines processes, enhances accuracy and improves decision-making.

Ready to modernize your warehouse and build accurate SKU master data? Talk to our team to integrate vMeasure Parcel Ultima with your preferred WMS or shipping software.

What is the difference between DIM weight and actual weight?

The actual weight is the exact weight of the product.

DIM weight also called volumetric weight calculates the amount of space a package occupies to its actual weight.

What is DIM weight pricing?

DIM weight pricing is a shipping calculation method that considers the volume of a package in addition to its actual weight. This pricing structure is used by many major shipping carriers, including UPS, FedEx, and the USPS.

Why is DIM weight pricing important?

It is important because helps shipping carriers to accurately calculate the shipping cost as it reflects the actual resources used by the carrier. Furthermore, it encourages shippers to use appropriately sized packages.

How to calculate dimensional weight?

Dimensional weight of the package = L * W * H / Dimensional Divisor

The dimensional divisor is carrier-specific. They vary from carrier to carrier.

How can I avoid overpaying for DIM weight pricing?

- Measure your packages accurately before shipping them.

- Use packaging that is the right size for your products, without any extra space.

- Negotiate with your shipping carrier if possible.

Talk to the dimensioning experts

Connect with our dimensioning experts and we will provide you with an in-depth analysis on how our vMeasure dimensioning solutions can save your time and money.