Table of Contents

Did you know that 72% of shippers end up in billing disputes because of inaccurate dimensions.

Dimensional data is a critical factor in calculating shipping charges. Especially, low density package fills more space on delivery trucks and helps in managing warehouse space efficiently.

Overestimating parcel dimensions end up in wasted storage spaces and underestimating parcel dimensions results in unexpected surcharges. This dimensioning dilemma is a challenge for businesses globally.

You would have heard about different parcel dimensioning systems in the market and wondered if you’re using the right one for your operations.

Your Dimensional Dilemma

Static Parcel Dimensioning: Precision in Place

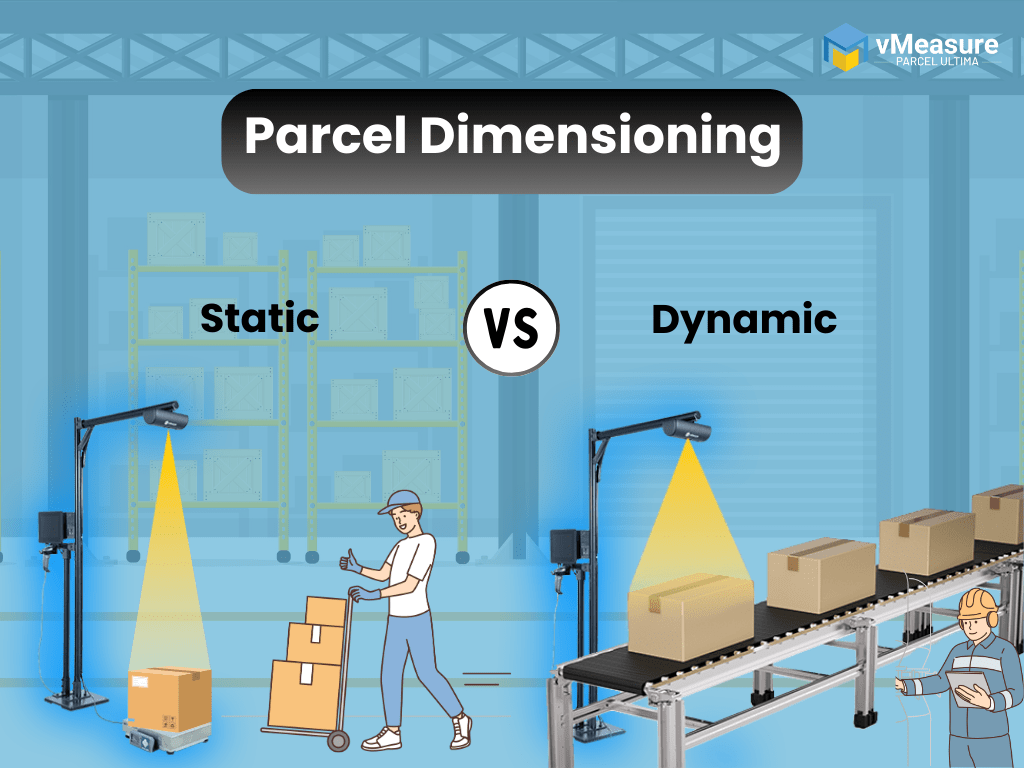

If your inventory consists of delicate or irregularly shaped items and with a consistent flow of parcels. Then consider using a static parcel dimensioning system where precision is the utmost need. A Static parcel dimensioning system dimensions parcels without the need for movement during the measurement process.

For example, a high-end electronic distribution center handles a mix of small and large parcels of fragile devices. A static parcel dimensioning system could efficiently measure the dimensions preventing any mishandling during transit.

Where To Use Static Parcel Dimensioning

Distribution Centers

In places where parcels move in a controlled and organized flow, static dimensioning systems, can be strategically placed to measure dimensions accurately without disrupting the overall operation.

Varied Parcel Sizes

In scenarios where parcels come in a diverse range of sizes. A Static dimensioning system can handle all irregular sized parcels accurately no matter how big or small they are.

Quality Control Stations

By adding a static parcel dimensioning system at key quality control checkpoints, we ensure that the parcel DIMs are checked accurately before they go to the next step in the supply chain. This helps us keep everything in good order and avoid mistakes.

Strategic Placement

Find important places in your work process where getting precise measurements is vital. This might be like places, where things come into the warehouse, at spots where quality is checked, or where things are packed.

Integration With Workflow

Integrate a static parcel dimensioning system as a natural part of your existing workflow to minimize disruptions. This might involve coordinating with conveyor systems or incorporating them into specific processing stations.

Dynamic Parcel Dimensioning: Efficiency in Motion

On the flip side, dynamic parcel dimensioning system works well in busy places that handle lots of packages quickly. They can measure parcels while they’re moving, making things smoother, especially in busy spots.

For example, an e-commerce company deals with thousands of parcels every single day, and parcels are constantly moving on conveyor belts as they make their way through the processing stages. Instead of stopping each parcel for dimensioning, which could slow everything down. Here dynamic parcel dimensioning systems can efficiently handle high volume packages without sacrificing accuracy.

Where To Use a Dynamic Parcel Dimensioning

Conveyor System

Dynamic parcel dimensioning systems can easily fit into conveyor systems, accurately dimensioning parcels while they move. This streamlines the operations by optimizing the throughput and reducing the processing time.

Busy Processing Station

Imagine a busy processing station at your warehouse where parcels are sorted, packed, or processed. By adding a dynamic parcel dimensioning system to these areas, accurate dimensions of parcels are taken without slowing down the workflow.

Automated Cross Belt Sorting Systems

In automated sorting systems, the focus is on streamlining the sorting process by capturing the parcel dimension accurately contributing to increased throughput and error-free sorting.

Real Time Measurement

When we say, “real-time measurement,” we mean getting measurements instantly and continuously. Dynamic parcel dimensioning system excel at providing immediate updates. As parcels move through the system, these dimensioning systems swiftly capture accurate measurements without delay.

Which Dimensioning System Should You Choose?

Ideally, the goal is to optimize the logistics processes for accuracy, efficiency, and overall cost-effectiveness. Always remember that there’s no one-size-fits-all solution. The choice between static and dynamic parcel dimensioning systems ultimately depends on your specific operational needs. Access your operational environment, parcel characteristics, and throughput requirements to determine the most suitable solution.

vMeasure dimensioning system can be mounted on a table, or placed on a floor, mobile cart, or a conveyor based on your operation needs. Talk to our experts to learn more about vMeasure Parcel Ultima.

What is the difference between DIM weight and actual weight?

The actual weight is the exact weight of the product.

DIM weight also called volumetric weight calculates the amount of space a package occupies to its actual weight.

What is DIM weight pricing?

DIM weight pricing is a shipping calculation method that considers the volume of a package in addition to its actual weight. This pricing structure is used by many major shipping carriers, including UPS, FedEx, and the USPS.

Why is DIM weight pricing important?

It is important because helps shipping carriers to accurately calculate the shipping cost as it reflects the actual resources used by the carrier. Furthermore, it encourages shippers to use appropriately sized packages.

How to calculate dimensional weight?

Dimensional weight of the package = L * W * H / Dimensional Divisor

The dimensional divisor is carrier-specific. They vary from carrier to carrier.

How can I avoid overpaying for DIM weight pricing?

- Measure your packages accurately before shipping them.

- Use packaging that is the right size for your products, without any extra space.

- Negotiate with your shipping carrier if possible.

Talk to the dimensioning experts

Connect with our dimensioning experts and we will provide you with an in-depth analysis on how our vMeasure dimensioning solutions can save your time and money.