Table of Contents

Introduction

Are you tired of inaccurate dimensions causing inefficient packaging and resulting in unavoidable shipping expenses?

You spend time and effort carefully packing your product, only to discover that it’s rattling around in an oversized box. Not only is this frustrating and wasteful, but it also negatively impacts your bottom line.

We are emerging to a world where precision meets automation, where your dimensioning machine seamlessly integrates with existing software to revolutionize the way packages are handled and shipped.

Let’s explore how the integration of dimensioners with the existing software can shape the future of shipping.

What Is the Future of Shipping?

Forbes predicts that the future trends of shipping and logistics industry will be shaped by automation, IoT (Internet of Things), sustainability. Embracing these trends will enhance efficiency, transparency, reliability, and ecofriendly. Ultimately, it’s all about meeting what customers want and expect.

Imagine a shipping ecosystem where every element communicates seamlessly — from warehouses and transportation systems to the very packages in transit. In the era of IoT, data is a valuable resource, essential for optimizing your work and ensuring customer happiness.

Learn how this can be achieved by integrating your system with the dimensioning machine.

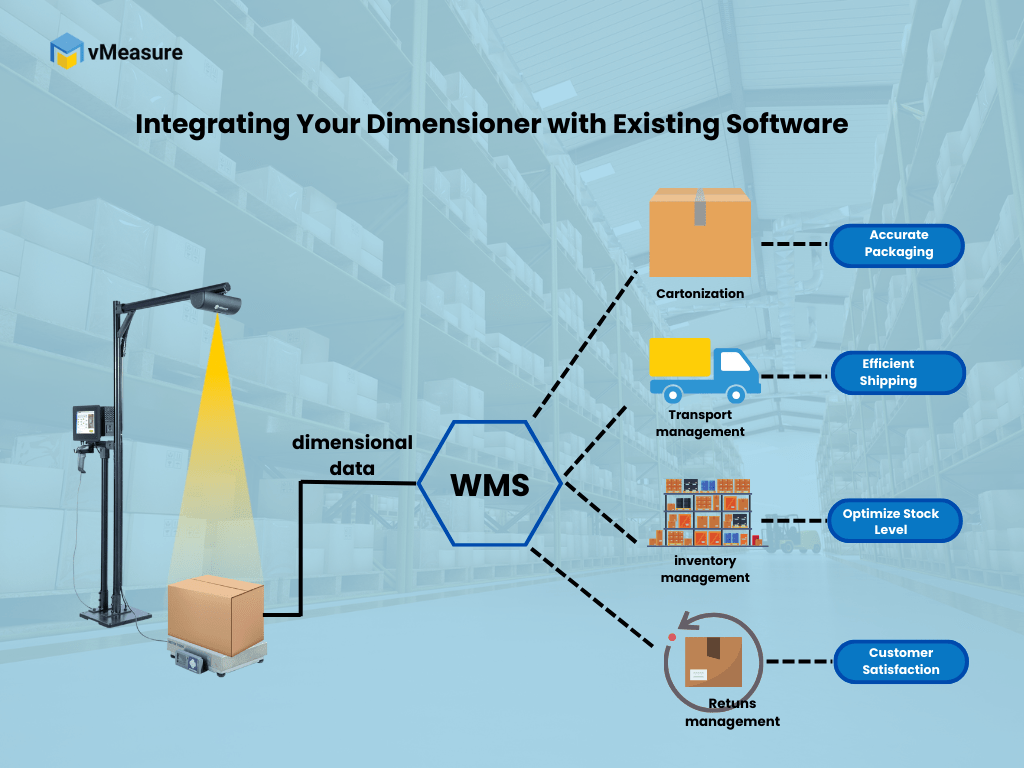

Integrating Dimensioners with Your System

Dimensioning machine offers a powerful solution by capturing the accurate parcel dimensions automatically. This parcel data is then seamlessly integrated with existing software systems, transforming the shipping process in several ways.

1. Power of Precision

As we highlighted, the future of shipping lies in integrating the dimensioner with the existing system. Forget about guessing sizes—now it’s all about accurate measurements. Dimensioning machines like vMeasure Parcel Ultima gives you the power to go beyond the limitations of the traditional method providing precise parcel measurements that leads to optimized workflow ensuring accuracy in every package. This data is then feed directly into your existing system like WMS (Warehouse Management System) that acts as fuel for operational efficiency, minimizing delays and overall shipping workflow.

2. Smart Storage Solutions

A transformative approach to warehouse optimization is by integrating the dimensioning machine with the WMS. Dimensional data enriches the creation of Master SKU data. This gives a holistic understanding of each product in the inventory. This helps in strategically storing each SKU based on its DIMs and weight further contributing to the faster retrieval and ensures every inch is utilized well.

3. Packing that Fits Like a Glove

If you are still packing products in a box that is 10 X size larger than the product itself, then these dimensioning machines can be integrated with cartonization software within the Warehouse Management Software (WMS). Once integrated, they compute the most efficient packaging configuration based on the accurate dimensions of the product aiding you to pack the item in a snugly fitted box. It’s not just about packing efficiently; it’s a thoughtful and sustainable way of shipping that meets the expectations of environmentally conscious customers.

4. Effortless Shipping Experience

The accurate dimensional data from the dimensioning machine when pushed into Transportation Management System (TMS) allows you to plan and optimize the shipment. This not only allow you to choose the right size package but also helps you avoid errors in calculating dimensional weight pricing. This reduces the risk of being charged incorrect rates and avoiding unexpected surcharges. TMS, coupled with dimensioners, enables real-time rate shopping by comparing shipping rates from various carriers.

5. Data Driven Decision

Integrating with dimensioner provide a wealth of data insights that aid in achieving data driven decision. Analysing this data provides a deeper understanding of shipping patterns, customer preferences, and potential areas for improvement.

In the future, businesses that take advantage of this data will hold a strategic edge. They will be able to adapt swiftly and innovate based on information that’s constantly updated in real-time

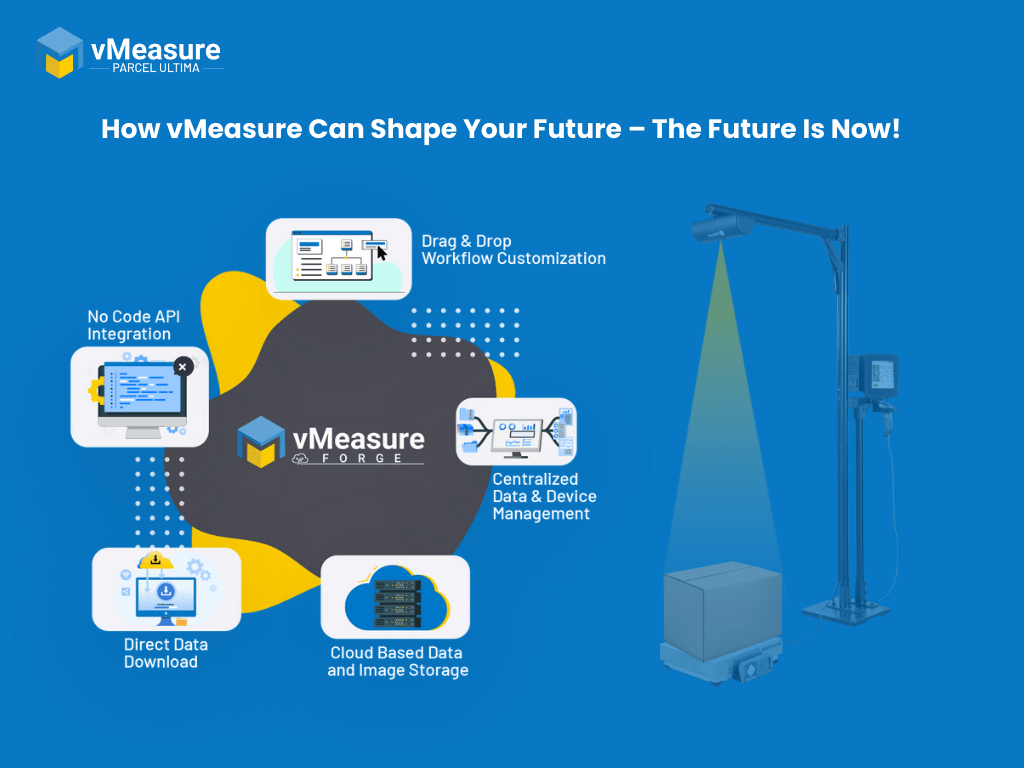

How vMeasure Can Shape Your Future – The Future Is Now!

Now that you are aware of the benefits of integrating a dimensioning machine with your existing software. Let’s talk about how easily it could be implemented with vMeasure Parcel Ultima. This camera vision dimensioner has already brought the future into the present, showcasing its limitless integration capabilities.

#1 No Code API Integration

Ease of Integration has been one of the biggest roadblocks to dimensioner. vMeasure makes it easy to connect to your existing system. You don’t have to be a coding expert because it doesn’t require complex API integration. This simplifies the process, saves time and making integration accessible by anyone.

#2 Customizable Workflow

Every business is unique. Hence, vMeasure is customized to meet those unique needs, eliminating the need for extra systems. This flexibility allows you to adjust the platform to suit your business requirements. This adaptability ensures that your workflows seamlessly match your operational needs, creating a more agile and responsive environment.

#3 Seamless Cloud-Based Solution

With vMeasure Forge discover the cloud-based solution that brings flexibility and scalability in managing data. Whether you’re a small business or a big one, vMeasure’s cloud integration makes data easy to access, and secure—all in one platform. It helps you grow your operations smoothly.

#4 Single-click Report Generation

Comprehensive report can be effortlessly generated which saves time and resources. The simple interface ensures even if you’re not a tech savvy, you can create reports that helps you make informed decision-making and optimize your operation.

#5 Data Analytics Dashboard

Data Analytics Dashboard in vMeasure Forge is the transformative force shaping your future by providing real-time insights, site level metrics, system level data, customizable analytics, and predictive capabilities. vMeasure empowers you to make strategic decisions today that will shape a more resilient and successful future for your business.

Did you know that using just the right-sized packaging can save enough cardboard to wrap the Earth multiple times?

It’s incredible but true. According to the Environmental Protection Agency (EPA), packaging accounts for about 30% of the municipal solid waste that goes to landfills in the United States. This means that we throw away about 67 million tons of packaging every year.

Conclusion

A company that understands not only what customers want but also knows how to refine their operations for maximum efficiency. It’s like having a roadmap for continuous improvement, ensuring that every step taken is informed by the latest insights. This strategic advantage positions businesses to stay ahead of the curve and excel in an ever-evolving world.

Ready to experience the future now? Take a leap and integrate your operations with vMeasure today

What is the difference between DIM weight and actual weight?

The actual weight is the exact weight of the product.

DIM weight also called volumetric weight calculates the amount of space a package occupies to its actual weight.

What is DIM weight pricing?

DIM weight pricing is a shipping calculation method that considers the volume of a package in addition to its actual weight. This pricing structure is used by many major shipping carriers, including UPS, FedEx, and the USPS.

Why is DIM weight pricing important?

It is important because helps shipping carriers to accurately calculate the shipping cost as it reflects the actual resources used by the carrier. Furthermore, it encourages shippers to use appropriately sized packages.

How to calculate dimensional weight?

Dimensional weight of the package = L * W * H / Dimensional Divisor

The dimensional divisor is carrier-specific. They vary from carrier to carrier.

How can I avoid overpaying for DIM weight pricing?

- Measure your packages accurately before shipping them.

- Use packaging that is the right size for your products, without any extra space.

- Negotiate with your shipping carrier if possible.

Talk to the dimensioning experts

Connect with our dimensioning experts and we will provide you with an in-depth analysis on how our vMeasure dimensioning solutions can save your time and money.

Ready to revolutionize your shipping process? Schedule a live call with our team to discover how our innovative solutions can drive your business forward.