Table of Contents

Introduction

Ever wondered why two packages, weighing the same, might have different shipping costs? Welcome to the world of Dimensional Weight Pricing! If you’re not careful, you could be overpaying for shipping. Some common mistakes are inflating your dim weight and increasing your shipping costs. In this blog post, we will show you how to avoid these mistakes and ship more efficiently.

Understanding DIM weight pricing

You might have heard of dim weight pricing. It is also called volumetric weight, a pricing method used by carriers to calculate the shipping cost based on the amount of space a package occupies to its actual weight. This prevents sending lightweight but bulky packages at a lower cost as it occupies valuable space on the truck or any shipping vehicle.

It might seem like a complicated and confusing concept, but it doesn’t have to be. Understanding dim pricing can help you save money and improve your packaging efficiency.

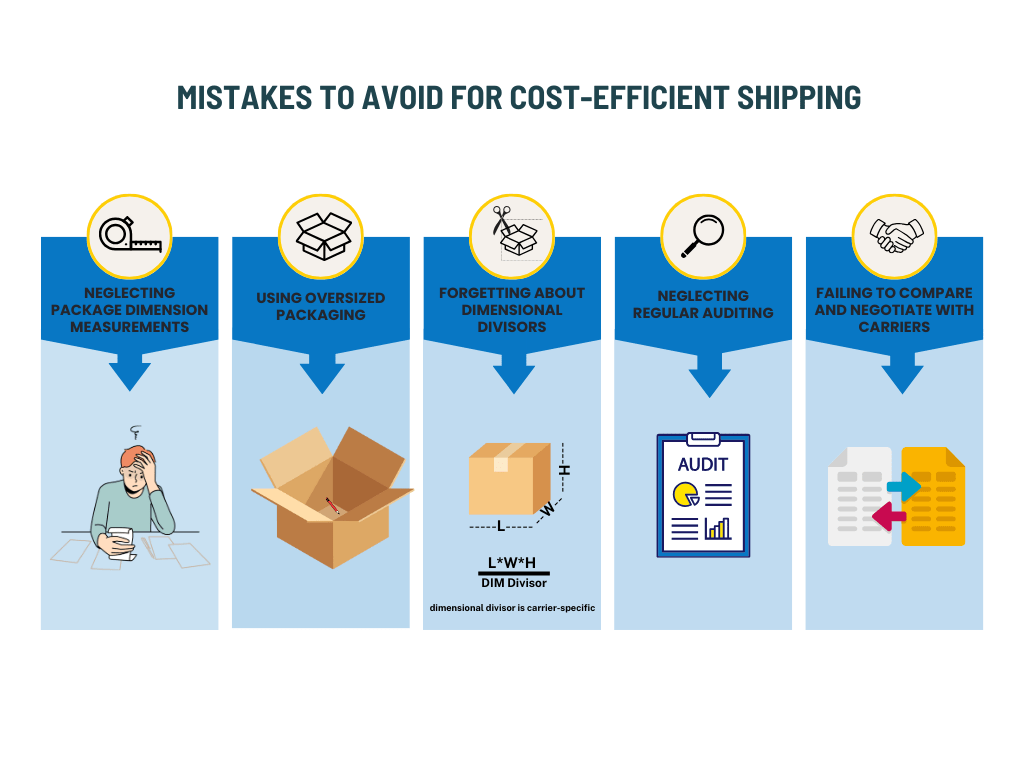

How to Avoid Common Mistakes with Dim Weight Pricing?

Mistake 1. Neglecting Package Dimension Measurements

The most common mistake made by shippers is not accurately dimensioning and weighing the package before shipping it to avoid being charged for excess DIM weight.

Ensure you measure the length, width, and height accurately, as even a slight miscalculation can lead to significant cost discrepancies. To avoid errors, you can invest in a dimensional weight system that can capture the dimensions faster and accurately.

Mistake 2. Using Oversized Packaging

For a lightweight small item, shipping on an oversized packaging can lead to higher dim weight for the wasted space and cost you high on shipping charges. This not only increases the shipping cost but also hurts the environment.

To avoid this, optimize your packaging by finding a perfect balance between protecting your products during transit and minimizing the dimensions of the package. To do so, accurately dimension and weigh the product. Knowing the accurate dimensions and weight of the product aids you in choosing the right-sized packaging.

Mistake 3. Forgetting About Dimensional Divisors

DIM weight pricing uses a factor called a dimensional divisor and often shippers mistake it to be common for all carriers. The dimensional divisor is specific values set to convert the dimensional measurement to chargeable weight. These divisors are carrier-specific, meaning they can vary from one carrier to another.

Neglecting these divisors can result in considerable miscalculations and unexpected shipping costs. By paying attention to the dimensional divisors, you can accurately estimate shipping expenses and make informed decisions about packaging and shipping methods.

Dimensional divisors are subject to change over time, so staying up to date with carrier-specific policies is essential for accurate DIM weight pricing.

Additionally, different carriers may apply different dimensional divisors based on factors like destination, service level, and package type.

Mistake 4. Neglecting Regular Auditing

It is important to perform a periodic review and assessment of your shipping and billing practices. Regular auditing ensures that you are aligned with the intended cost-efficiency goals as the DIM weight pricing is intricate and carrier-specific.

By consistently auditing, you can identify discrepancies between estimated and actual shipping costs. This helps you catch errors in dimensional weight calculations, packaging choices, or rate negotiations that may be costing your business unnecessary expenses.

Mistake 5. Failing to Compare and Negotiate with Carriers

There are many times when shippers miss out on potential cost savings by failing to negotiate or compare the shipping rates with carriers.

- Different carriers have different dimensional weight pricing, and delivery times for different destinations and services. By comparing them you can find a cost-effective and efficient option for shipments.

- If you are shipping in large volumes, carriers are always open to negotiation. Explore your options and negotiate a deal that suits your budget and shipping needs.

Did you know that using just the right-sized packaging can save enough cardboard to wrap the Earth multiple times?

It’s incredible but true. According to the Environmental Protection Agency (EPA), packaging accounts for about 30% of the municipal solid waste that goes to landfills in the United States. This means that we throw away about 67 million tons of packaging every year.

Frequently Asked Questions

What is the difference between DIM weight and actual weight?

The actual weight is the exact weight of the product.

DIM weight also called volumetric weight calculates the amount of space a package occupies to its actual weight.

What is DIM weight pricing?

DIM weight pricing is a shipping calculation method that considers the volume of a package in addition to its actual weight. This pricing structure is used by many major shipping carriers, including UPS, FedEx, and the USPS.

Why is DIM weight pricing important?

It is important because helps shipping carriers to accurately calculate the shipping cost as it reflects the actual resources used by the carrier. Furthermore, it encourages shippers to use appropriately sized packages.

How to calculate dimensional weight?

Dimensional weight of the package = L * W * H / Dimensional Divisor

The dimensional divisor is carrier-specific. They vary from carrier to carrier.

How can I avoid overpaying for DIM weight pricing?

- Measure your packages accurately before shipping them.

- Use packaging that is the right size for your products, without any extra space.

- Negotiate with your shipping carrier if possible.

Add Ons: Misconceptions You Have Heard

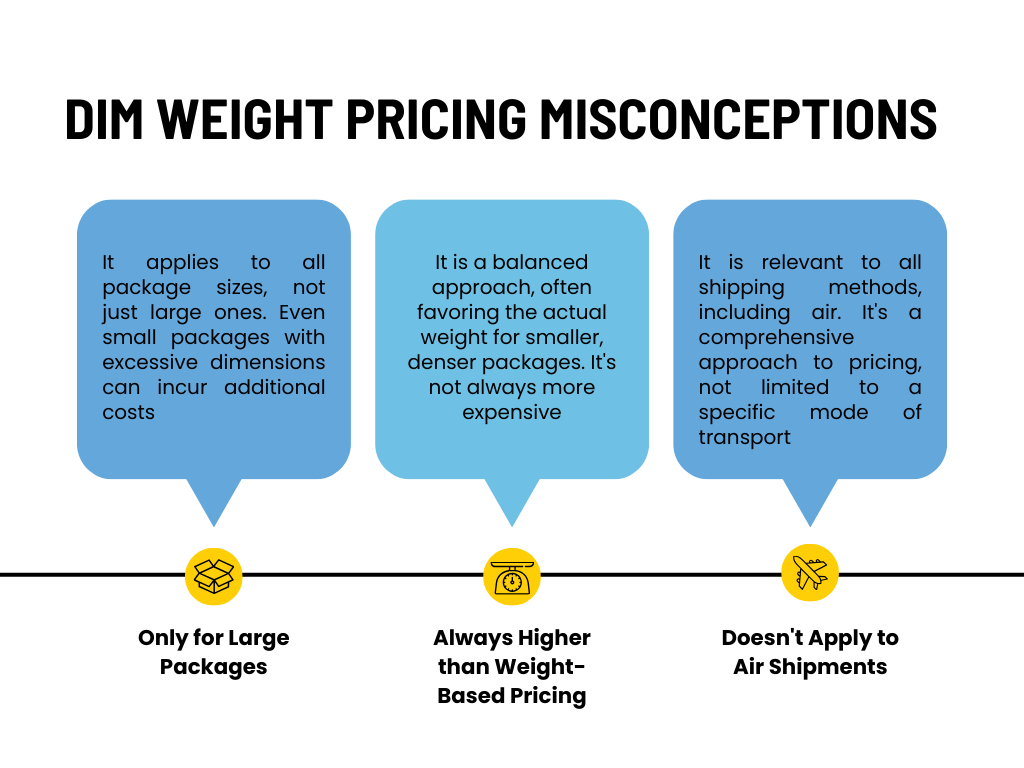

As we explored mistakes to avoid, it is necessary to discuss the misconception about DIM weight pricing.

Now let’s throw some light on the most common misconception you heard of.

DIM Weight Pricing is Only for Large Packages

It’s not true as it seems. Though it affects large packages and packages that are lightweight but bulky, DIM weight pricing applies to any package, regardless of size. Shippers need to be aware that accurate dimensions play a substantial role, and using excessively large packaging for small items can result in costlier shipments.

DIM Weight Pricing is Always Higher than Weight Based Pricing

It is easy to see why shippers believe this – after all, considering both weight and package dimensions seems like it should result in higher costs, right? It’s always not the case. DIM weight pricing is designed to promote fair pricing and discourage the use of oversized packaging for lightweight items. Hence, it gives the shippers potential cost savings and environmental benefits when packaging practices are optimized.

DIM Weight Pricing Doesn’t Apply to Air Shipments

DIM weight pricing is not associated only with ground shipments. It can apply to various modes of transformation. Dimensional weight pricing is typically higher for air shipments than for ground shipments. This is because air carriers have more limited space and capacity than ground carriers, so they need to be more efficient with their space utilization.

Conclusion

By avoiding DIM weight pricing mistakes and optimizing packaging practice you can lead to substantial cost savings and a more sustainable approach to shipping. Keep these insights in mind as you strive for cost-efficient shipping in your industry. Furthermore, ensure to understand and address the common misconception as it is vital for shippers looking to reduce shipping costs and enhance their logistics operations.

Talk to our experts to know how dimensional weight systems can measure accurately and quickly to save you from overcharges.

Ready to revolutionize your shipping process? Schedule a live call with our team to discover how our innovative solutions can drive your business forward.