Table of Contents

Introduction

Imagine you are in a situation where you must ensure your warehouse operation runs smoothly and efficiently but you don’t have enough workers to handle the workload which in turn affects your productivity, profitability, and customer satisfaction. You are not alone.

Any successful online business can be nerve-racking as labor shortages in warehouses can cause turmoil. The soaring costs, and delays in deliveries, put your reputation on the line. It’s a make-or-break moment. Fear not. Discover how dimensioning systems can rescue your operations, slash costs, and ensure happy customers.

Labor Crisis in Warehouse

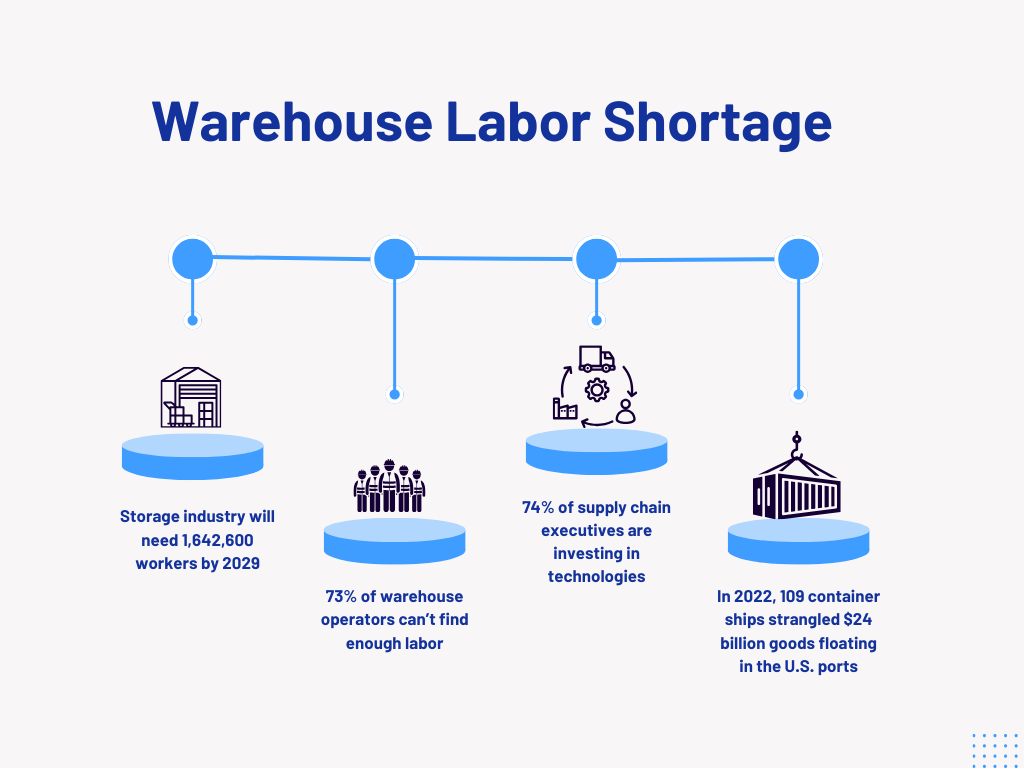

The warehouse labor shortage is a global problem. Forbes states that, over a year ago, the labor shortage and pandemic e-commerce demand created a record of 109 container ships strangled $24 billion in goods floating in the U.S.’s Port of Long Beach in California.

According to the U.S. Bureau of Labor Statistics (BLS), the warehousing and storage sector is expected to require a workforce of 1,642,600 employees by the year 2029. The industry struggles with retaining workers to meet demand due to an aging workforce and limited young recruits.

Transform your Productivity with Dimensioning System

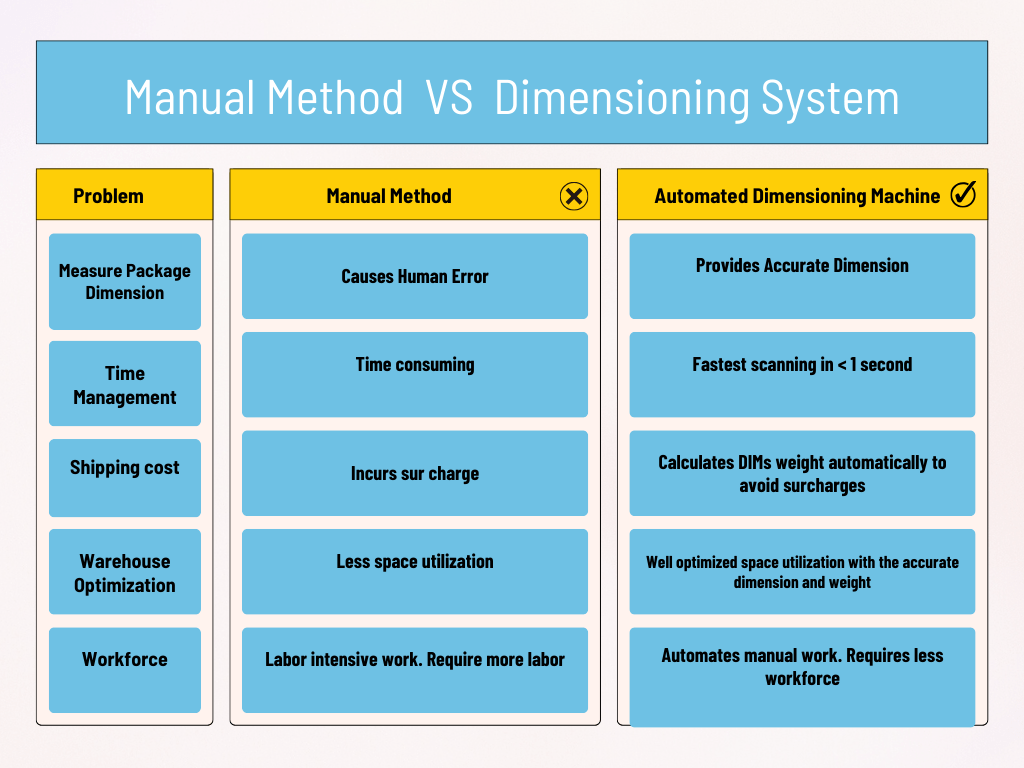

Dimensional weight systems like vMeasure Parcel Ultima Pro can accurately dimension and weigh packages within a second. This automated cubic system not only automates labor-intensive tasks and reduces the need for manual work. It can additionally optimize your warehouse in various ways such as:

1. Increases Throughput

With the fastest and most accurate scanning, the dimensional weight system can scan more packages in less time than manual methods or outdated equipment which increases your existing labor productivity and efficiency.

2. Reduces Shipping Cost

The accurate dimension and weight data reduces manual errors and discrepancies in shipping costs. You can avoid overpaying for shipping or undercharging your customers, which can improve your profitability and customer satisfaction.

3. Optimizes Space Utilization

Using a dimensional system, you optimize your warehouse space utilization with the accurate dimensions and weight of your inventory. You can use this data to plan your storage layout, slotting, picking, packing, loading, and unloading processes. You can also reduce your inventory shrinkage by detecting damaged or missing items.

4. Reduces Labor Costs

By improving efficiency and accuracy, the dimensioning system can reduce the cost of hiring new employees and train them. They can reduce your labor dependency by up to 50%, slashing the need for manual labor in measuring and weighing packages. As they are easy to use and require minimal supervision.

Did you know that using just the right-sized packaging can save enough cardboard to wrap the Earth multiple times?

It’s incredible but true. According to the Environmental Protection Agency (EPA), packaging accounts for about 30% of the municipal solid waste that goes to landfills in the United States. This means that we throw away about 67 million tons of packaging every year.

Redefine Recruitment and Retention Strategies

In the current market, workers have more expectations which makes recruitment and retention a big challenge. On the other hand, common challenges faced by warehouse managers are high turnover rates, low productivity, skill gaps, and safety issues.

With the help of a dimensioning system, you can focus on attracting and retaining employees by accelerating their work with advanced technology.

The following benefit of the dimensional weight system not only overcomes the labor shortage but helps warehouse handle operations effectively.

- Reduced Physical Workload

The demanding physical tasks at a warehouse are measuring the package dimensions accurately, weighing the package or pallet, and carrying heavy loads. Installing a dimensional weight system reduces the workload and improves the productivity and profitability of the warehouse.

- Improved Work Environment

Dimensioning systems can help to create a more organized work environment by reducing manual handling. This can lead to improved morale and productivity among warehouse workers. However, create a comfortable and safe environment. Warehouse workers who feel valued are more likely to stay.

- Provide Opportunities for Professional Development

Warehouses can provide training and development opportunities to help their employees advance their careers. Using advanced technology machines employees can develop their skill and knowledge.

- Streamlined Workforce Management

Labor scheduling software helps you schedule labor effectively, ensuring that you have the right number of employees on hand to meet demand. Dimensioning System can be easily integrated with existing labor scheduling software allowing you to allocate labor resources based on real-time needs.

What is the difference between DIM weight and actual weight?

The actual weight is the exact weight of the product.

DIM weight also called volumetric weight calculates the amount of space a package occupies to its actual weight.

What is DIM weight pricing?

DIM weight pricing is a shipping calculation method that considers the volume of a package in addition to its actual weight. This pricing structure is used by many major shipping carriers, including UPS, FedEx, and the USPS.

Why is DIM weight pricing important?

It is important because helps shipping carriers to accurately calculate the shipping cost as it reflects the actual resources used by the carrier. Furthermore, it encourages shippers to use appropriately sized packages.

How to calculate dimensional weight?

Dimensional weight of the package = L * W * H / Dimensional Divisor

The dimensional divisor is carrier-specific. They vary from carrier to carrier.

How can I avoid overpaying for DIM weight pricing?

- Measure your packages accurately before shipping them.

- Use packaging that is the right size for your products, without any extra space.

- Negotiate with your shipping carrier if possible.

Make Data Driven Decision

In today’s competitive business environment, data-driven decision-making assists you to stay informed about how to run a business. This can include decisions about everything from product selection to marketing strategies to warehouse operations.

Dimensioning systems are an asset for making data-driven decisions. It collects data on package dimensions which can be used to improve warehouse operations.

- Identify Bottlenecks in Warehouse Operations

If your warehouse is experiencing delays in order fulfillment, dimensioning system data can be used to identify the process that is causing the delays like picking and packing. Once the bottlenecks have been identified, the warehouse can take necessary steps to address them.

- Optimize Warehouse Layout

Leveraging the DIM data obtained from the dimensional weight system, you can determine the best location for storage, picking stations, and shipping docks. This can help to improve warehouse efficiency and reduce costs.

- Improve Inventory Management

The Package data retrieved from dimensional weight system can be used to track inventory levels and identify items that are low in stock. Moreover, the availability of accurate inventory data enhances the likelihood of products being in stock, further reducing customer frustration.

- Forecast Demand

Dimensional weight system can be used to forecast demand for products. This can help warehouses to plan their operations more effectively and ensure that they have enough inventory on hand to meet demand.

- Customer Satisfaction

The precision data from the dimensional weight system helps you provide seamless and satisfying service to your customers by ensuring that their orders are processed correctly and delivered on time.

Conclusion

The current labor shortages in the warehousing industry present a unique opportunity for businesses to reevaluate their operational strategies and embrace new technologies. Among the many solutions available, dimensioning systems stand out as a versatile tool that can address multiple challenges simultaneously.

By implementing dimensioning systems, warehouses can effectively mitigate labor costs, boost productivity, enhance order accuracy, uplift customer service quality, and optimize their storage space. Furthermore, the adoption of dimensional weight system provides a competitive advantage in the market, positioning businesses for sustainable growth and success.

Ready to revolutionize your warehouse operations with dimensioning systems? Connect with our dimensioning experts today and discover how this game-changing technology can supercharge your business!

Talk to the dimensioning experts

Connect with our dimensioning experts and we will provide you with an in-depth analysis on how our vMeasure dimensioning solutions can save your time and money.

Ready to revolutionize your shipping process? Schedule a live call with our team to discover how our innovative solutions can drive your business forward.