Table of Contents

Introduction

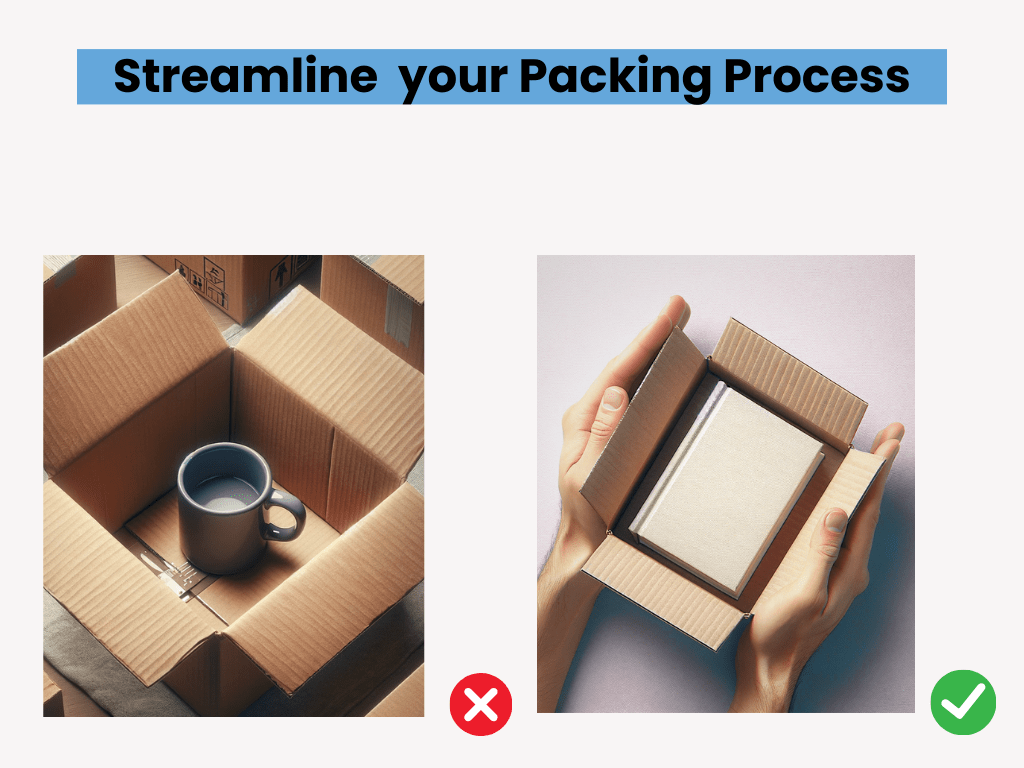

No person who would ever say I haven’t received a small item on an oversized package when you ordered a product online. The internet is flooded with images of an Airpod or tiny tub of cream or just a pack of cookies in a box as 10 X size large as it can fit a master pack of the item they have shipped.

But have you wondered why e-commerce giants like Walmart and Amazon ship tiny items in huge boxes? Why spend resources on excessive packaging materials, incur additional shipping expenses, and contribute to environmental problems?

Let’s, dive into the problem and discover the solution that can enhance and streamline the packing process.

Why Pack Small Items on an Oversized Box?

Problem 1: Wrong Product Dimensions

Retailers depend on data from the suppliers for accurate dimensions. However, they don’t always get it right. Because of,

- Data entry errors: Suppliers manage large inventories of data by using outdated equipment or traditional methods to dimension the product leading to incorrect data entry such as mistaking feet for an inch.

- Incomplete or generic information: Sometimes, product descriptions may lack accurate dimensions or use generic measurements. Retailers may not have precise information, especially for items that are sourced from different suppliers.

Solution: Accurate and Fast Dimension

Investing in a precise dimensional weight system like vMeasure Parcel Ultima can effectively address the inaccuracies in measurements and eliminate the need to depend on supplier-provided data. The dimensional weight system can dimension any type of product accurately and fast which in turn reduce human errors.

These systems offer real-time measurements, ensuring that accurate dimensions are readily available when needed. This feature is particularly useful for retailers dealing with products from a variety of suppliers, where precision is crucial.

Problem 2: Limited Packing Option

Businesses often find themselves constrained by a finite selection of box sizes and types, for packaging their products. This limited packing option makes them choose from the closest available box size for various products, even if it’s larger than necessary. This happens mostly when they lack SKU master data with the exact details of the products leading them to prefer definite box sizes.

Solution: Pack it Right

Dimensioners can be customized to meet the business expectation. While capturing the accurate dimensions it also allows to add customized attributes that aid in building the master SKU data.

Moreover, dimensional weight system seamlessly integrates with the cartonization software within the Warehouse Management System (WMS), which computes the most efficient packaging configuration for individual units or cases.

Choosing the appropriate package can result in significant savings on shipping costs. When you tend to ship more air than the product, you end up paying additional shipping charges as carriers use DIM weight pricing to calculate the shipping cost.

Problem 3: Standard Size Boxes are Easy to Stack and Pack

Operations consider that uniform-sized boxes can be easily and neatly stacked on pallets and shelves making storage and transportation straightforward. They believe even sized packages are easy to load and unload.

Solution: Optimal Packing and Stacking

Operations assume that uniform-sized boxes simplify the packing process. However, employing a dimensioner that provides precise measurements and weight data of inventory can ease the process. This information can be effortlessly integrated with a Warehouse Management System (WMS) to strategize storage layout, slotting, picking, packing, as well as loading and unloading operations.

Problem 3: Large Boxes Avoid Damage due to Transit

Large boxes are often seen as protective shields for small items during transit. It is assumed that huge boxes have extra room for protecting the packages with packing peanuts or bubble wrap that can be safely transported without damaging the product.

Solution: Right-sized Box Keeps the Product Stay Intact

Reducing product damage is important, yet businesses need to understand that right-sized packages minimize the risk of damage and reduce shipping costs. The right package with the right amount of package fillers helps the goods or items stay intact and avoid movement during transit.

With accurate measurements from dimensioners, businesses can calculate the exact amount of padding required for each shipment. This ensures that small items are well-protected without the need for oversized boxes. Smaller, yet accurately sized boxes cost less to ship and can still provide sufficient protection.

Additional Factors and Considerations in Selecting the Right-sized Box

There are certain additional factors and considerations that businesses should consider when making packaging decisions.

#1 Sustainability

Oversized boxes require more packaging materials, such as cardboard, bubble wrap, and packing peanuts contributes to excess waste, which can harm a business’s reputation and contribute to environmental issues.

#2 Improved Customer Service

Customers are frustrated when they see a tiny item in an oversized size box. It not only erodes the trust but also impacts the overall shopping experience as they expect their orders to arrive in appropriate packaging.

Businesses should prioritize customer service using a dimensional weight system to ensure that the boxes are just the right size, are easy to handle, and require less time to pack. This makes a frustration-free packing and enhances overall efficiency.

#3 Impact on Supply Chain Efficiency

The choice of packaging is not just related to the packing station, but it can have far-reaching consequences, affecting logistics, warehousing, transportation, and the overall flow of products from the manufacturer to the end consumer.

Making informed decision using dimensioner can improve the supply chain efficiency as it is widely used in receiving and packing stations.

Did you know that using just the right-sized packaging can save enough cardboard to wrap the Earth multiple times?

It’s incredible but true. According to the Environmental Protection Agency (EPA), packaging accounts for about 30% of the municipal solid waste that goes to landfills in the United States. This means that we throw away about 67 million tons of packaging every year.

Conclusion

So, why pack small items in a huge box when you can streamline your packing process, reduce costs, and become more environment friendly? Oversized boxes might not be the best choice for your business. Instead, consider implementing dimensioners that can enhance your overall supply chain efficiency.

If you would like to streamline your packing process effectively. Talk to our expert to find the right fit for your unique shipping needs.

What is the difference between DIM weight and actual weight?

The actual weight is the exact weight of the product.

DIM weight also called volumetric weight calculates the amount of space a package occupies to its actual weight.

What is DIM weight pricing?

DIM weight pricing is a shipping calculation method that considers the volume of a package in addition to its actual weight. This pricing structure is used by many major shipping carriers, including UPS, FedEx, and the USPS.

Why is DIM weight pricing important?

It is important because helps shipping carriers to accurately calculate the shipping cost as it reflects the actual resources used by the carrier. Furthermore, it encourages shippers to use appropriately sized packages.

How to calculate dimensional weight?

Dimensional weight of the package = L * W * H / Dimensional Divisor

The dimensional divisor is carrier-specific. They vary from carrier to carrier.

How can I avoid overpaying for DIM weight pricing?

- Measure your packages accurately before shipping them.

- Use packaging that is the right size for your products, without any extra space.

- Negotiate with your shipping carrier if possible.

Talk to the dimensioning experts

Connect with our dimensioning experts and we will provide you with an in-depth analysis on how our vMeasure dimensioning solutions can save your time and money.

Ready to revolutionize your shipping process? Schedule a live call with our team to discover how our innovative solutions can drive your business forward.